Thermal control in electronic assemblies may require a combination of heat sinks and fans. Air ducts have been employed to minimize heat sinks, fans and cost. A heat-moldable, flexible, non-elastic, semi-rigid thermally and electrically insulating polyethylene phthalate polymer substrate with 0.36 mm thickness withstands temperatures greater than the semiconductor safe operating range. The substrate forms an arc between case apertures and heat producing semiconductors and over mechanical obstructions to yield directed and laminar flow. Substrates separate components in cases where more than one thermal control system exists. It has been shown that the designs of electronic systems with conventional combination of heat sinks and fans can be altered to create higher-efficiency systems. These improved systems contain electronic assemblies with sufficiently spread thermal gradients to optimize heat transfer and to keep semiconductors within safe operating temperatures. The coupling of internal subassemblies allows constructive interference in air flows to multiply cooling effect. The non-elastic, semi-rigid polyethylene phthalate substrates hereafter referred to as ThermoChannel substrates permit systems with fewer moving parts to lower both noise and cost.

Inventor: Ray, James S., Jr. (Raleigh NC) http://www.neuse.net

What is claimed is:

1. Field of the Invention

The present invention relates to the removal of heat from semiconductors of electronic assemblies inside cases and, more particularly, to the thermal control achieved through the use of ThermoChannel substrates that form thermal channels for laminar air flow.

2. Description of Related Art

In order to remove heat from semiconductors inside the cases of electronic assemblies, others have stacked a heat sink and fan on top of a heat-producing semiconductor mounted on a printed circuit board.

A disadvantage of this arrangement, however, is that the height of the heat sink and fan requires a larger case. Another disadvantage is that the fan produces noise. Even though lower profile fans that yield a total system height of 1.75” to fit in a 1U 19” rack mount case are available, horizontally-mounted fans direct air into the top of the system case. The resulting disturbance from mechanical interference produces noise and is less efficient at cooling than the laminar flow of the vertically-mounted fans with ThermoChannel technology.

One solution to the aforementioned problems is to eliminate the fan. By placing a ThermoChannel substrate that directs air to and from the heat sink without a fan directly attached, it has been shown that the core temperature does not increase. Thus, a simple and economical ThermoChannel substrate replaces an expensive and noisy fan.

Accordingly, it is desirable to design systems containing heat producing semiconductors with ThermoChannel substrates that form thermal channels to efficiently remove heat from the case.

A ThermoChannel substrate forms thermal channels within electronic assembly cases to efficiently remove heat. Three types of thermal channels are combined to produce a system. Thermal channel type 1 couples entrances and exits on cases of electronic assemblies to heat producing semiconductors. Thermal channel type 2 forms an arc over mechanical obstructions inside cases of electronic assemblies to produce laminar air flow. Thermal channel type 3 provides a barrier in systems where more than one thermal channel exists.

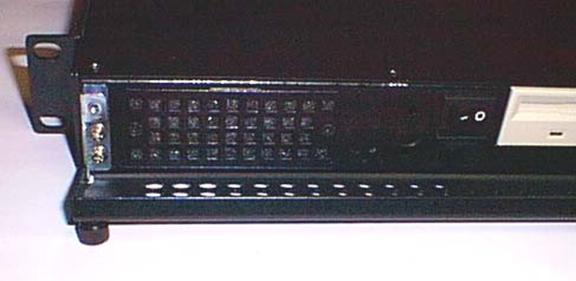

Fig. 1: Case for an Electronic Assembly with Top Cover Removed

Fig. 2: Noise-Producing Fans Removed from Final Assembly

Fig. 3: Conventional Heat Sink and Fan and Mechanical Constraint of Case

Fig. 4: Plan View of Electronic Assembly with ThermoChannel Substrates

Fig. 5: Critical Application of ThermoChannel Substrate at Heat Producing Semiconductor

Fig. 6: Side View of ThermoChannel Substrate at Heat Producing Semiconductor

Fig. 7: Case for Electronic Assembly Front View

Fig. 8: Air Flow Diagram at Semiconductor Heat Source

Fig. 9: Air Flow Diagram over Horizontal Obstructions

Fig.10: Diagram of Electronic Assembly Case from Horizontal Perspective

Fig. 11: Electronic Assembly Case Front Mounted Fans

Fig. 12: Electronic Assembly Case Side Aperture – Exterior View

Fig. 13: Electronic Assembly Case Side Aperture – Interior View

Fig. 14: Constructive Interference

Fig. 15: Air Flow Diagram Prior to Modification

Fig. 16: Air Flow Diagram After Modification

Fig. 17: Air Flow Diagram for Vertical ThermoChannel Substrate

© 2005 Neuse River Network, Inc.

Jim Ray, MCSE, Senior Member, IEEE (member for 24 years)

Server, Workstation and Network Specialist - Commercial and Open Source Solutions

Low Monthly Cost, Scheduled Maintenance, 24/7 Emergency Services

Neuse River Network, Inc. · 2610 Vanderbilt Ave. · Raleigh, NC

27607-7247

Tel: 919-838-1672 · Toll Free: 800-617-7652

jim (at) neuse.net · http://www.Neuse.Net

Commercial and Industrial Computer Networks - Serving the Triangle area since 1997